One Stop Shop

The road towards Vertical Integration - Collaboration between ASCO, UAC Vietnam and UAC Europe

Written by Anne Swanson

Lead, In-house Consultancy

Montana Aerospace

Asco, Uac Vietnam & UAC Europe

are involved in a strategic collaboration to transfer parts currently produced by external suppliers, and bring them in-house to provide greater control of the Supply Chain, reduce costs and increase margins across the Montana Aerospace Group.

This enables us to capitalise on existing capabilities across the entities and to work towards our collective vision of vertical integration within the Montana Aerospace Group.

Since April 2024, UAC Vietnam has been working closely with our colleagues at ASCO Belgium, ASCO Canada and ASCO US to industrialize parts for Boeing, Airbus and Embraer via Sonaca and Spirit, thus extending the end customer portfolio and extending the expertise and capability in Vietnam. Through working to achieve additional qualifications for a variety of processes and surface treatments, UAC Vietnam is extending its service offering to further consolidate the Montana Aerospace Group´s position as a one stop shop for the Aerospace industry.

In addition, this transfer has provided an opportunity for expansion into the production of Super Alloy parts at UAC Vietnam, as well as to leverage the capacity and capability of UAC Europe to industrialize a variety of complex Stainless Steel and Titanium parts.

This collaboration has brought our sister companies much closer together, by leveraging expertise and knowledge transfer across the Montana Aerospace Group.

It also creates significant advantages for our customers in terms of protection of the Supply Chain i.e. reducing risk by reducing the number of suppliers in the chain, increasing quality, and reducing the production time thus enabling faster delivery of parts to our customers.

Overall, this collaboration consolidates our position as a Tier 2 player in the Aerospace market; increases our competitiveness and attractiveness to both our current and prospective customers; and ensures a very strong and prosperous future for us all in the Montana Aerospace Group.

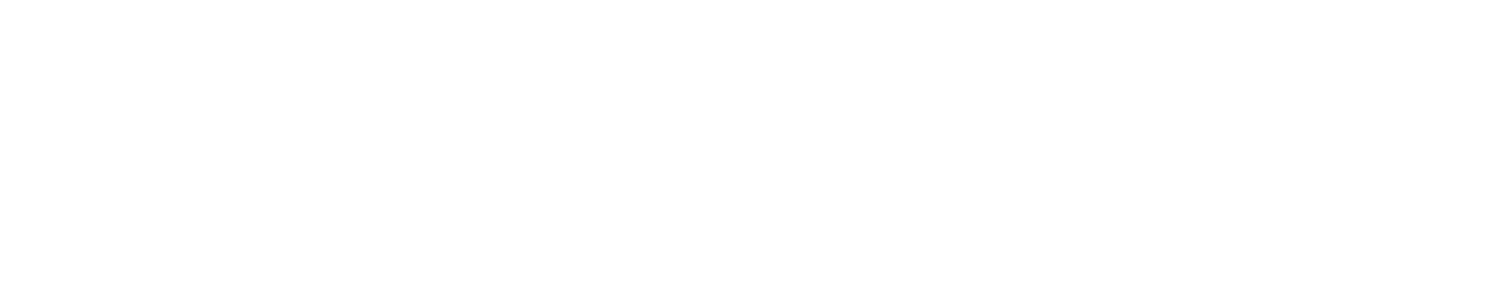

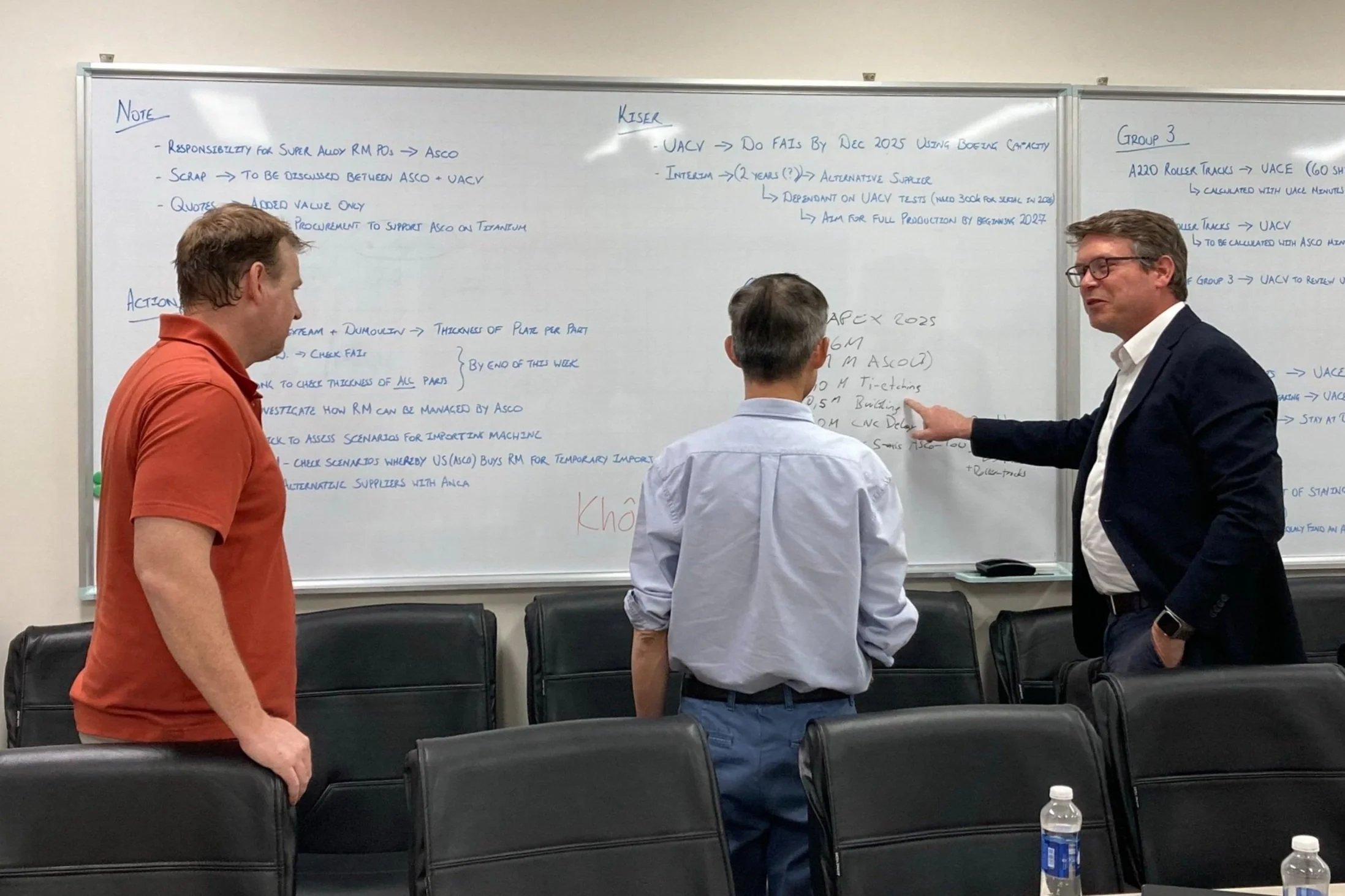

To facilitate this collaboration, workshops have been held at UAC Vietnam in April 2025 together with Senior Management from ASCO and UAC Europe. Jerome Morhet, CEO of ASCO remarked, “We did more in 3 hours together, than we would have done in a week at a distance”, thus highlighting the benefit of direct collaboration and hands-on working sessions with the counterparts across the entities.

To date, more than 250 parts have been industrialized, and a further 650 parts are currently under industrialization, illustrating the significant opportunity for the Montana Aerospace Group in terms of cost reduction by creating greater economies of scale and thus lowering our variable production costs, increased revenues, greater control of the Supply Chain, and capability development across the Group.

Mac Truong

CEO UAC Vietnam

“If you want to go fast, go alone. If you want to go far, go together. This joint workshop between UAC and Asco management reflects our commitment to going further—together. By aligning roles, sharing insights, and combining strengths, we are not just solving today’s challenges—we are building a more connected, efficient, and resilient Montana Aerospace Group for the future.”

Brian Weed

CEO UAC Europe

“UAC Europe has the opportunity to capitalize on our hard metal capabilities for the benefit of Asco, whilst securing the supply chain for the Montana Aerospace Group overall.”

Jerome Morhet

CEO Asco

“By combining the skills at our 3 entities, we are reducing costs for Montana Aerospace and actively contribute to the “Road to Competitiveness” Transformation Plan of Asco”

We recognize and appreciate the great efforts of the teams actively working on this transfer, and are energized by the dedication & motivation demonstrated in the formation of our cross-company teams.